Product Introduction

Transposition wire is a winding wire made by arranging a certain number of enameled flat wires in two columns in a special process and continuously weaving them, and wrapping them with specific insulation materials. Mainly used for manufacturing windings of large oil immersed power transformers, reactors, and large capacity dry-type transformers. The use of transposed wires to manufacture transformers increases the space utilization of windings, reduces volume and costs, and lowers the additional losses caused by circulating currents and eddy currents due to leakage magnetic fields. At the same time, it also increases the mechanical strength of the winding and saves winding time. Continuous transposition wire is a material required for manufacturing transformer windings. It has high space utilization, good heat dissipation performance, low eddy current loss, high mechanical strength, less coil winding time, and good process performance.

Range

Paper insulated aldehyde enameled transposition wire

Paper insulated self-adhesive acetal enameled transposition wire

Paper insulated self-adhesive semi-rigid aldehyde enameled transposition wire

Paperless binding type aldehyde enamel coated transposition wire

Ladder transposition combination wire

Internal screen transposition combination wire

Polyester imine enameled transposition wire

Polyvinyl alcohol and polyester film insulated transposition wire

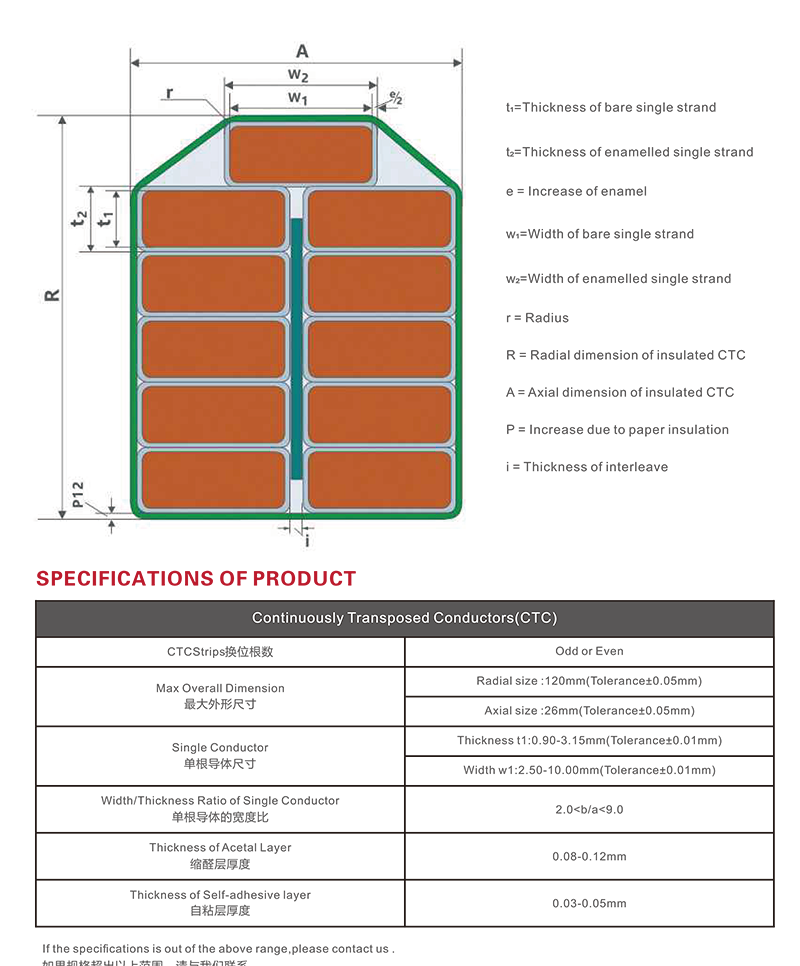

Production scope:

Number of transposed roots: 5-80 roots (odd or even numbers are optional);

Dimensions: Height 120mm, width 26mm (tolerance ± 0.05mm);

Single conductor size: thickness a: 0.90-3.15 mm, width b: 2.50-13.00 mm (tolerance ± 0.01mm);

The recommended width to thickness ratio for a single conductor is 2.0

The recommended coating thickness for enameled wire is 0.08-0.12 mm, and the adhesive layer thickness is 0.03-0.05 mm.

NANTONG BAIWEI ELECTRIC CO., LTD

MOBILE:13506297676

TEL:0513-88360458

FAX:0513-88360388

EMAIL:ntbwe@163.com

ADDRESS:No. 16, middle development avenue, Haian Development Zone, Jiangsu Province

Copyright ? 2015-2018 NANTONG BAIWEI ELECTRIC CO., LTD All rights reserved. All rights reserved

Non-operational ICP number of the People's Republic of China:蘇ICP備17018192號-1